ตามปกติแล้ว หลอดไฟ Metal Halide (ชนิดหนึ่งของ HID) ถูกผลิตขึ้นมาเป็นรูปทรงกลมเนื่องจากมีหลอดไฟมีรูปทรงกลม ซึ่งโคมไฟ HID ไม่สามารถที่จะผลิตออกมาเป็นรูปทรงเหลี่ยมเหมือนกับกับหลอดไฟฟลูออเรสเซนต์

โคมไฟไฮเบย์รุ่นแรกๆ ถูกออกแบบตามโคมไฟเมทัลฮาไลด์ ซึ่งมีรูปทรงกลมเช่นเดียวกัน ซึ่งรูปร่างของโคมไฟก็จะขึ้นอยู่กับจำนวนของชิปที่อยู่ภายโคมไฟในยุคนั้น โคมไฟ LED ไฮเบย์กำลังไฟสูงและโคมไฟเมทัลฮาไลด์ต่างใช้ตัวสะท้อนแสงเพื่อช่วยปรับทิศทางของแสง

ความก้าวหน้าด้านเทคโนโลยีช่วยให้สามารถใช้ชิปจำนวนที่มากขึ้น แต่มีกำลังไฟฟ้าที่มีกำลังต่ำลง เพื่อช่วยในการกระจายความร้อนได้ดียิ่งขึ้น ซึ่งในช่วงเวลานั้นเอง ผู้ผลิตก็ได้มีทางเลือกในการที่จะวางเรียงชิพที่มีกำลังไฟต่ำในรูปแบบแนวเส้นตรง หรือรูปแบบวงกลม เช่นเดียวกับชิปที่มีกำลังไฟสูงรุ่นแรกของโคมไฟ LED ไฮเบย์ ทำให้โคมไฟ LED ไฮเบย์แบบกลมเป็นทางออกในกลุ่มตลาดที่ต้องการจัดวางตำแหน่งไฟแบบเดิมแต่ต้องการเปลี่ยนและติดตั้งเพิ่มเติม

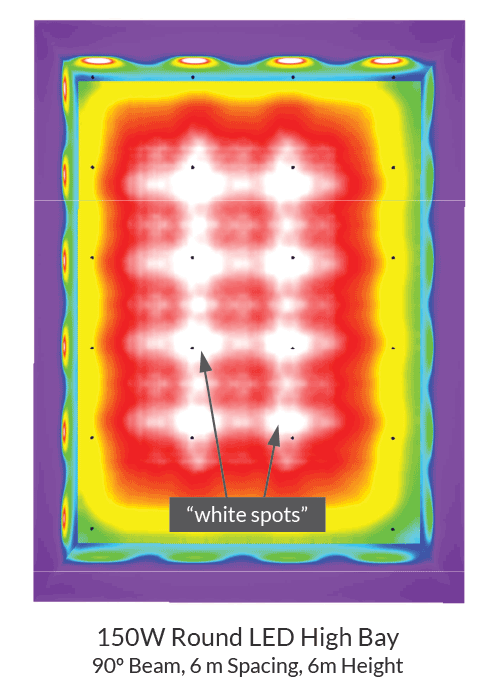

แต่ในทางกลับกัน กลุ่มตลาดที่สร้างโรงงานใหม่ ต้องการวางระบบไฟแบบใหม่ทั้งหมด มักเลือกใช้ไฟ LED ไฮเบย์แบบบาร์ ด้วยเหตผลที่ว่าไฟ LED ไฮเบย์แบบบาร์สามารถวางและจัดตำแหน่งได้เหมาะกับ layout ของโรงงานมากกว่าแบบกลม เพราะทั้งทางเดินและชั้นเก็บสินค้าล้วนเป็นทรงเหลี่ยมทั้งนั้น อีกเหตุผลหนึ่งก็คือ โคมไฟ LED ไฮเบย์แบบบาร์ ไม่ทำให้เกิดจุดสว่างเฉพาะจุด (“white spots”) เหมือนกับแสงจากโคมไฟ LED ไฮเบย์ทรงกลม